Hellenic Cables represents the cable production and marketing sector of Viohalco and is one of the largest cable producers in Europe. The Company started its activities in 1950 as a Viohalco plant and in 1973 it was incorporated as an independent subsidiary under the name Hellenic Cables, expanding its production and trade operations. Today, Hellenic Cables consists of Hellenic Cables S.A. which operates three plants in Viotia, Greece that produce cables, enamelled wires, plastic and elastomer compounds; the Fulgor S.A. plant in Corinth, Greece, which manufactures power cables, submarine cables and copper wires; and Icme Ecab S.A., a power and telecommunication cable manufacturer in Bucharest, Romania.

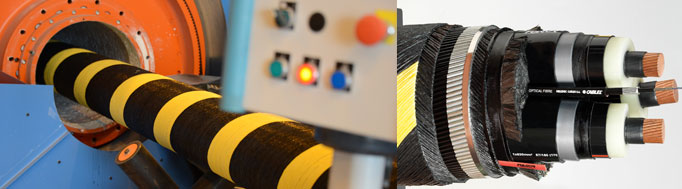

With a strong export orientation and focus on development of value added products, such as high and extra-high voltage cables and submarine cables, the Group makes significant investments towards enriching its product portfolio and enhancing its sustainability profile. In 2012, the Company completed a EUR 50 million investment plan for the manufacture of high-voltage submarine cables in Fulgor's plant.

The Company's wide product range, which is sold internationally, extends to PVC, EPR and XLPE insulated power cables (rated up to 500kV), marine and low smoke halogen free cables, fire resistant cables, telecommunication, signal and data cables with copper conductors or optical fibres, as well as fire retardant halogen free plastic and elastomer compounds and enamelled wires. Wires and cables are supplied to a variety of international standards, such as VDE, CEI, NF, SEN, BS, UL, NEMA, JIS, ASTM, DIN and ELOT. Many of the Company's products are certified by ELOT, BASEC, VDE, IMQ, NF-USE, NETWORK RAIL, KEMA, DNV and UL.

All enamelled wires are manufactured and tested to the IEC 60317-0-1 standard; customers may also request any other recognised international standard.

Technical know-how from world leaders such as the VISCAS Corporation is combined with continued investment in state-of-the-art machinery to ensure levels of efficiency and quality which meet the strictest standards. The Company's Quality Management System is certified to ISO 9001:2008, its Environmental Management System to ISO 14001:2004 and its Occupational Health and Safety to OHSAS 18001:2007. Commitment to quality and sustainable development has been a key factor in enabling Hellenic Cables to establish a strong market position internationally. The Company's highly experienced technical and managerial staff have a strong commitment to technological excellence and outstanding quality, which ensures that users of the products have made a reliable choice.

Hellenic Cables aims to constantly improve its offering and respond swiftly to changes in customer needs around the world with reliable, safe products, based on environmentally-friendly technologies. At the same time, the Group places strong emphasis on the development of its people and the creation of value for its shareholders, partners and the communities in which it operates. Looking ahead, the Group plans additional investments in technology and innovative cable solutions as a way of contributing to the creation of a sustainable future for its stakeholders.

Hellenic Cables product range

Power cables

- Indoor installation cables

- Control cables

- Industrial and outdoor installation cables

- Fire retardant, fire resistant, halogen-free cables

- Medium Voltage Cables

- High voltage and Extra High Voltage cables

- Copper conductors for grounding applications and overhead Cu, Al and ACSR conductors

- Ship and marine installations fire resistant cables

- Copper and Aluminium rods

Telecommunications and data transmission cables

- Gauging and control cables

- Copper conductor cables: Conventional telephone cables - Telephone exchange cables - Data transmission cables – High frequency telephone cables

- Optic fibre cables (single-mode &multi-mode): Underground dielectric cables, in tubes - Underground dielectric cables, directly buried (steel reinforcement) Underground dielectric cables, featuring rodent protection - Indoor installation LSZH cables (central tube or tight buffered)

- Aerial installation cables (“8”-sized or ADSS)

- Signalling & railway signalling cables

Submarine cables

- Medium voltage and High Voltage cables

- Composite Medium voltage and High Voltage cables with integrated Optic fibre cables

- Optic fibre cables

Plastic and rubber compounds

- PVC-based plastics

- Polyolefin-based plastics

- Elastomers

Enamelled wires

- Winding wires for electric motors and transformers

- Copper wires for grounding earthing and canmaking

Applications

Cables used in:

- Buildings

- Outdoor installations and industrial applications

- Transmission and distribution networks

- Installations with special requirements

- Ships and marine applications

- Telecommunications and data transmission networks

- Renewable energy sources

- Islands - continental system interconnections

- Offshore Aeolic parks interconnections

Enamelled wires are used in:

- Transformers

- Motors – generators

- Small motors

- Relays – coils

- Self-supporting windings-avoids varnish impregnations

Compounds are used in:

- Cable industry

- Production of soft water pipes

- Production of flexible spiral pipes

- Production of hard flexible pipes for electrical applications

- Rubber and plastic soles

- Flexible elastic and plastic profiles

Turnkey solutions

Hellenic Cables has the necessary know-how to develop and offer turnkey solutions that meet specific demands of its customers. The Company provides:

- Design and manufacture of products according to customer requirements and project specifications

- Provision of special equipment needed for cable connections and termination of cable ends

- Transportation and installation of cables at the project site

- Civil works required for installation and protection of cables

- Testing, initial operation and delivery of the system to the customer (commissioning)

- Full Project Management

- Customer staff training in system operation and maintenance

- Provision of maintenance / support to the customer